Degradable plastic refers to the plastic that a certain amount of additives (such as starch, modified starch or other cellulose, photosensitizers, biodegradants, etc.) added in the production process to reduce its stability and then easily degrade in the natural environment. Tests have shown that most degradable plastics begin to thin, lose weight, lose strength, and gradually break into pieces after 3 months of exposure in the general environment. If these fragments are buried in garbage or soil, the degradation effect is not obvious.

1. Photodegradable plastic:

A photosensitizer is added to the plastic to gradually decompose the plastic under sunlight. It belongs to an earlier generation of degradable plastics, and its disadvantage is that the degradation time is difficult to predict due to changes in sunlight and climate, so the degradation time cannot be controlled.

2. Biodegradable plastic:

It can be completely decomposed into low molecular compounds under the action of microorganisms. It is characterized by convenient storage and transportation, as long as it is kept dry, it does not need to be protected from light, and it has a wide range of applications. With the development of modern biotechnology, more and more attention has been paid to biodegradable plastics, and it has become a new generation of research and development hot spots.

Biodegradable plastics are roughly divided into 7 types

Global Plastics Network believes that polylactic acid (PLA) is a new type of biodegradable material made from starch raw materials proposed by renewable plant resources such as corn. It is understood that the amount of PLA accounts for 45.1% of biodegradable plastics, and it is a well-deserved main force!

PHA is an aliphatic copolyester with different structures synthesized by microorganisms through the fermentation of various carbon sources. Among them, the most common ones are poly-3-hydroxybutyrate (PHB), polyhydroxyvalerate (PHV) and copolymer of PHB and PHV (PHBV). The main uses are: disposable tableware, non-woven fabrics, packaging materials, agricultural film, toys, film, glue, fiber and other degradable products.

PHA degradable plastic has the best performance among biodegradable plastics. At the same time, due to its high cost and complex production process, it is still in the initial stage of the market. In 2010, the global PHA production capacity was less than 80,000 tons, of which Metabolix in the United States had a production capacity of about 50,000 tons, accounting for more than 60% of the market. Chinese enterprises are also leading the way in PHA production technology and research and development. Tianjin Guoyun Biomaterials Co., Ltd. has a PHA production capacity of 10,000 tons, Ningbo Tianan has a production capacity of 2,000 tons, and Shenzhen Yikeman Biotechnology Co., Ltd. has a production capacity of 5,000 tons. tons of production capacity. Japan’s Kaneka Company and Brazil’s PHBIndustrial Company are also typical representatives of the PHA industry. These companies are all promoters of the PHA industry. Although the application of PHA is relatively limited, the actual sales volume of Metabolix per year does not exceed 100 tons. The gradual expansion of downstream applications in the future, especially the further maturity of applications in film packaging, agricultural film, edible tableware, non-woven fabrics and other industries, the market potential of PHA is huge.

Polyε-caprolactone (PCL) is a low-melting polymer obtained by ring-opening polymerization of ε-caprolactone, and its melting point is only 62°C. The degradability of PCL has been studied since 1976. In both anaerobic and aerobic environments, PCL can be completely decomposed by microorganisms.

PBS uses aliphatic succinic acid and butanediol as the main raw materials for production, which can not only meet the demand through petrochemical products, but also can be produced through biological fermentation through natural renewable crop products such as starch, cellulose, and glucose, so as to achieve Green circular production that comes from nature and returns to nature. Moreover, the raw materials produced by the biological fermentation process can also greatly reduce the cost of raw materials, thereby further reducing the cost of PBS.

The aliphatic aromatic random copolyester (Ecoflex) manufactured by German BASF company, its monomers are: adipic acid, terephthalic acid, 1,4-butanediol. The current production capacity is 140,000 tons/year. At the same time, biodegradable plastic products based on polyester and starch have been developed.

Water-soluble PVA film is a new type of plastic product emerging internationally. It utilizes the film-forming, water and biological degradation properties of PVA, and can be completely degraded into CO2 and H2O. It is a veritable green high-tech environmental protection packaging material.

A new type of synthetic material under study, which uses carbon dioxide as a monomer raw material and is activated to a high degree under the action of a bimetallic coordination PBM catalyst, undergoes a copolymerization reaction with an epoxide to form aliphatic polycarbonate ( PPC), after post-treatment, carbon dioxide resin material is obtained. Domestic Inner Mongolia Mengxi Group Co., Ltd. adopts the technology of Changchun Institute of Applied Chemistry and has built a device with an annual output of 3,000 tons of carbon dioxide/epoxy compound copolymer resin. The products are mainly used in packaging and medical materials.

3. Photo/biodegradable plastics:

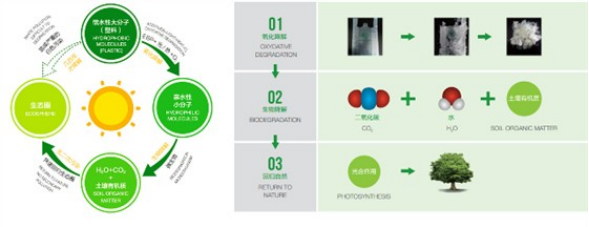

A type of plastic that combines photodegradation and microorganisms, and it has the characteristics of photodegradable and microbial degradable plastics at the same time.

Water-degradable plastics: Add water-absorbing substances to plastics, which can be dissolved in water after use. It is mainly used in medical and sanitary utensils (such as medical gloves), which is convenient for destruction and disinfection.

4. Starch-based plastics

So far, starch-based degradable plastics mainly fall into four categories: filled type, photo/biodegradable type, blend type and all-starch plastic.

Natural starch molecules contain a large number of hydroxyl groups to form strong hydrogen bonds within and between molecules, and the molecular polarity is larger, while the polarity of synthetic resins is smaller and is a hydrophobic substance. Therefore, native starch must be surface-treated to improve hydrophobicity and compatibility with polymers. There are mainly two methods of physical modification and chemical modification.

Japan developed modified starch/EVOH copolymer blended with LDPE, dimethylsiloxane epoxy modified starch, and then blended with LDPE. Mster-Bi plastics of Italian company Novamont and NoVon series products of American Warner-lambert company also belong to this kind of products. Mster-Bi plastic is a polymer alloy formed by the physical cross-linked network of continuous EVOH phase and starch phase. Since both components contain a large amount of hydroxyl groups, the product is hydrophilic, and the mechanical properties will decrease after water absorption, but it is insoluble in water.

This is a technology that has not been understood by most people in China. Additives are added to the traditional plastic production raw materials, which is the same as the general color masterbatch addition method. After the plastic products are abandoned, two substances in the additives play a role: one is a pre-oxidant (mainly some non-toxic metal ions), and the other is a biodegradation promoting substance (mainly some natural plant cellulose). The pre-oxidant controls the plastic to maintain its due life and function when it is not abandoned, and reduces the molecular weight through the peroxidation reaction after abandonment, making the polymer brittle and easy to be decomposed by microorganisms. Biodegradation promoting substances are mainly to promote the growth of microorganisms. Compared with starch-based plastic technology, this technology is simple and easy to implement, and the cost is reduced. It can be produced by general equipment. According to relevant verifications, the performance of the plastic has also been well maintained. Save food. The British WELLS company adopts this method.

Simple identification method of common plastics Before using various plastic recycling methods to reuse waste plastics, most of the plastics need to be sorted. Since there are many and complex plastic consumption channels, and some post-consumer plastics are difficult to distinguish simply by their appearance, it is best to indicate the material variety on plastic products. China has formulated GB/T16288-1996 “Plastic Packaging Products Recycling Mark” with reference to the material variety marking proposed and implemented by the American Plastics Association (SPE). Although the above marking method can be used to facilitate sorting, there are still many unmarked products in China In order to separate different types of plastics for sorting and recycling, we must first master the knowledge of identifying different plastics.

Appearance identification

By observing the appearance of plastics, it is possible to preliminarily identify the major categories of plastic products: thermoplastics, thermosetting plastics or elastomers. General thermoplastics are crystalline and amorphous. Crystalline plastics are translucent, opalescent or opaque in appearance, transparent only in film state, and range in hardness from soft to horny. Amorphous is generally colorless, completely transparent when no additives are added, and its hardness is harder than that of horny rubber (additives such as plasticizers are often added at this time). Thermosets usually contain fillers and are opaque, such as transparent without fillers. The elastomer has a rubber-like feel and a certain stretch rate.

Heat identification

The heating characteristics of the above three types of plastics are also different, which can be identified by the heating method. Thermoplastics soften when heated, melt easily, become transparent when melted, can often draw filaments from the melt, and are usually easy to heat seal. Thermosetting plastics are heated until the material is chemically decomposed, and its original hardness is not softened, and its size is relatively stable, and it is carbonized at the decomposition temperature. When the elastomer is heated, no flow occurs until the chemical decomposition temperature, and the material is decomposed and carbonized at the decomposition temperature.