1. Description

| Capacity | 10g 30g |

| OEM | We can make new molds as required |

| Use | Cream etc |

| Logo printing | Available |

| MOQ | 3000/size |

| Packing | Carton with grid inside and pallet is available |

| Payment | 30%T/T prepaid,the balance before delivery |

| Delivery | Within 45days after down payment and samples’ approval |

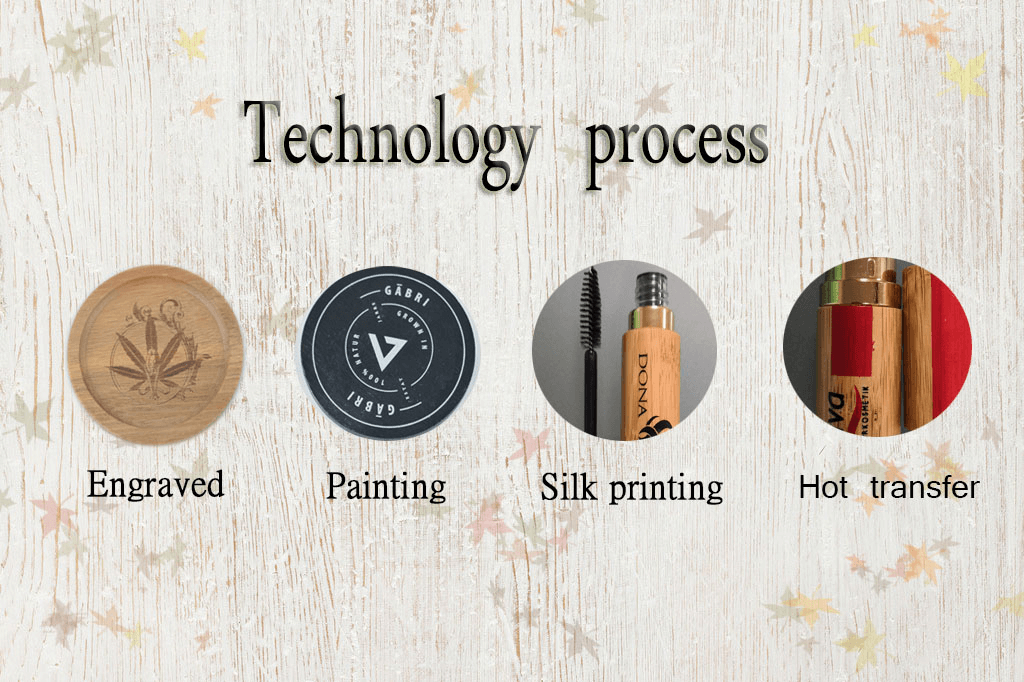

| Our service | Available to customize the items according to your sample& design or OEM& ODM. Printing your logo on the box or engraving any image with the product are also warmly welcome. |

| Samples policy | If you give quick enquiry, 5 free samples are available.The express freight charges should be on buyer’s account. |

| Silk printing,UV coated,Hot stamping,frosted,painting etc can be available. | |

2. Feature of Product

1.Uzone’s bottles are widely used in the personal care industry.

2.Different size,volumes,style,color of bottles are available

3.Customer designs available.

4.Samples are available at our existing shape.

5.Conform with USA,Europe Stand

40 ton furnace, 200000 bottles per day, 4 row and column machines, single drop line, 50000 bottles per day.

Advanced temperature control equipment controls the temperature of each stage of bottle annealing to ensure the toughness of the product.

Patrol inspection of production line, full inspection of packing, full inspection before leaving factory to ensure the quality of products delivered to customers.

Full set of testing equipment, professional inspection knowledge training, to ensure the professionalism of all quality inspection personnel.

Both frosting and sandblasting are used to cover the glass surface, so that the light will diffuse relatively evenly after passing through the lampshade. It is difficult for ordinary users to distinguish between these two technologies.

1. The frosting process

Frosting refers to immersing the glass in a prepared acid liquid (or applying an acid paste), corroding the glass surface with strong acid, and the hydrogen fluoride ammonia in the strong acid solution makes the glass surface crystals. Therefore, if the frosting process is done well, the surface of the frosted glass is very smooth, and the scattered crystals produce a hazy effect. If the surface is relatively rough, this indicates that the acid is severely eroding the glass, or some of them still have no crystals. The characteristic of this process is the appearance of shiny crystals on the glass surface formed under critical conditions. The main reason is that the hydrogen fluoride ammonia has almost been consumed. In order to achieve this state, many manufacturers have made many attempts and studies, but have not been able to overcome this difficulty.

2. Sandblasting technology

It uses the sand particles ejected by the spray gun at high speed to hit the glass surface to form a fine uneven surface, thereby achieving the effect of scattering light, and forming a hazy feeling when light passes. The surface of the glass products produced by the sandblasting process is rough. Because the surface of the glass is damaged, it looks like white glass in terms of the photosensitivity of the original transparent glass.