1. Description

| Capacity | 30g 50g 80g 100g 150g 200g |

| OEM | We can make new molds as required |

| Use | Cream etc |

| Logo printing | Available |

| MOQ | 5000/size |

| Packing | Carton with grid inside and pallet is available |

| Payment | 30%T/T prepaid,the balance before delivery |

| Delivery | Within 45days after down payment and samples’ approval |

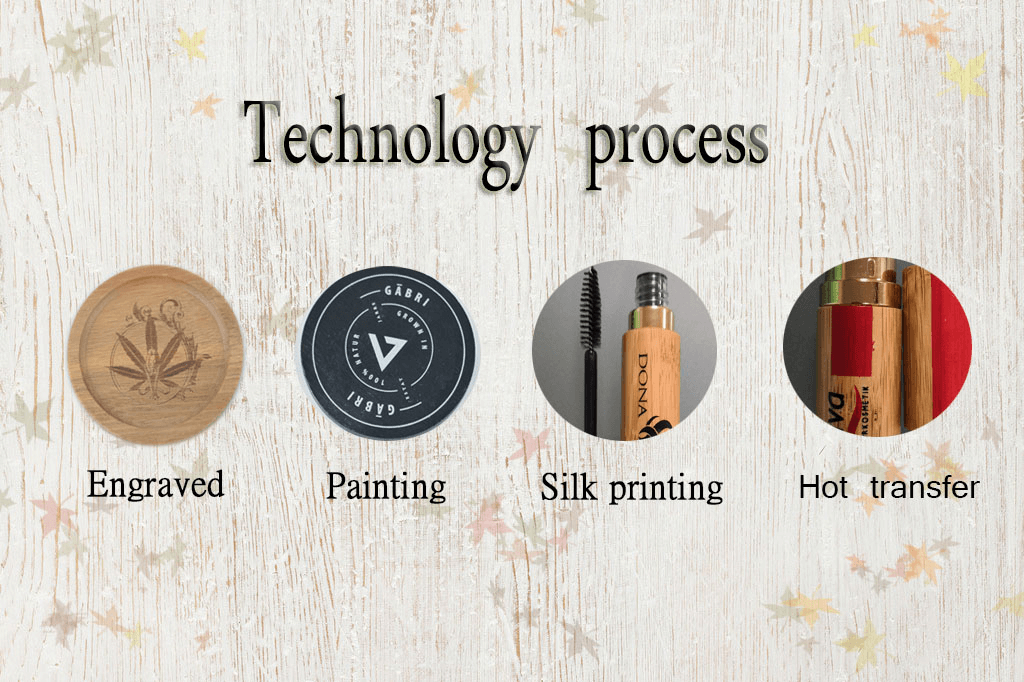

| Our service | Available to customize the items according to your sample& design or OEM& ODM. Printing your logo on the box or engraving any image with the product are also warmly welcome. |

| Samples policy | If you give quick enquiry, 5 free samples are available.The express freight charges should be on buyer’s account. |

| Silk printing,UV coated,Hot stamping,frosted,painting etc can be available. | |

2. Feature of Product

1.Uzone’s glass bottles are widely used in the personal care industry.

2.Different size,volumes,style,color of glass bottles are available

3.Customer designs available.

4.Samples are available at our existing shape.

5.Conform with USA,Europe Stand

40 ton furnace, 200000 bottles per day, 4 row and column machines, single drop line, 50000 bottles per day.

Advanced temperature control equipment controls the temperature of each stage of bottle annealing to ensure the toughness of the product.

Patrol inspection of production line, full inspection of packing, full inspection before leaving factory to ensure the quality of products delivered to customers.

Full set of testing equipment, professional inspection knowledge training, to ensure the professionalism of all quality inspection personnel.

There are two processes for glass bottle production: manual machine and rank machine. The glass bottles produced are different to some extent. You can refer to the following points for identification:

1. The craftsmanship of the mold line and the glass bottle body mold line are the same, that is, in a straight line, but the manual machine is not necessarily in a straight line.

2. The production of the cooling flower bottom row machine at the bottom of the glass bottle is clear, but the production of the manual machine is not clear and obvious.

3. Since the manual machine is cooled by water and the assembly line process is cooled by air and wind, the smoothness of the glass bottle body produced is smoother and more uniform than that of the manual machine, and the bottle wall is clearer and more transparent.

4. Blind marks can not be seen on the bottom of the glass bottles produced by manual machines, while obvious blind marks can be seen in the assembly line of the assembly line.

5. Put several glass bottles together. The bottles produced by the assembly line look neat and even the angles of reflection are consistent.

In general, the glass bottle production line is much better than glass bottles produced by manual machines. It can adapt to the automatic production of various filling machines and sealing machines.